- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- सीमेंट

- उर्वरक

- औद्योगिक रसायन

- थोक प्रसाधन सामग्री रंगद्रव्य

- जिंक सल्फेट हेप्टा/जिंक सल्फेट/कैस 7446-20-0

- जिंक क्लोराइड निर्जल

- सोडियम फॉर्मेट 92% 95% 98%

- सोडियम हाइपोक्लोराइट 10% -15%

- कैल्शियम क्लोराइड 74% 77% फ्लेक रीच के साथ

- मैग्नीशियम ऑक्साइड दानेदार

- डिटर्जेंट के लिए SLES 70% सोडियम लॉरिल ईथर सल्फेट SLES

- गामा ब्यूटिरोलैक्टोन

- सफेद फेनोलिक पाउडर

- एक्टिवेटेड कार्बन

- बायोसाइड लिक्विड ग्लूटाराल्डिहाइड

- हॉट सेल स्टाइरीन मोनोमर कैस 100-42-5

- हाइड्राज़िन हाइड्रेट 35% 40% 55% 64% 80% 100%

- IBC ड्रम पेरोक्साइड में शीर्ष गुणवत्ता वाला हाइड्रोजन 35% 50%

- डिहाइड्रेटिंग एजेंट/इपा

- सिलिकॉन इमल्शन

- मेथनॉल इथेनॉल अल्कोहल एथिल अल्कोहल 99.9% औद्योगिक ग्रेड

- सोडियम फ्लोराइड क्रिस्टल

- फेरस सल्फेट

- उर्वरक अमोनियम सल्फेट

- बेंज़ालकोनियम क्लोराइड BKC 45% 50% 80%

- बेस्ट क्वालिटी होलसेल आयरन ड्रम पैक्ड कैस 109-66-0 पेंटेन

- 99% शुद्धता सोडियम मोलिब्डेट 7631-95-0

- फेनोलिक राल के लिए सर्वोत्तम मूल्य और उच्च शुद्धता वाला फिनोल

- एपॉक्सीडाइज्ड सोयाबीन ऑयल

- सफेद कास्टिक सोडा पाउडर

- सोडियम कार्बोनेट पाउडर

- पोटेशियम कार्बोनेट पाउडर

- प्रोपलीन ग्लाइकोल एल्गिनेट

- सिलिकॉन डाइऑक्साइड

- ग्लुकोनो डेल्टा लैक्टोन (GDL)

- सोडियम प्रोपियोनेट

- मटर का प्रोटीन

- कैल्सियम साइट्रेट

- एन पेंटेन

- एसिटिक एसिड

- सोडियम फॉर्मेट 97%

- फेरस सल्फेट पाउडर

- लीनियर अल्काइल बेंजीन सल्फोनिक

- प्रोपलीन ग्लाइकोल

- ब्रोमीन।

- रासायनिक विश्लेषणात्मक अभिकर्मक

- खाद्य और पेय पदार्थ

- सोयाबीन का बीज

- जैविक सोयाबीन

- कच्चे काजू के टुकड़े

- बादाम का आटा

- भुना हुआ नमकीन बादाम

- हल्के भुने हुए बादाम अनसाल्टेड

- बिना नमक के भुने हुए काजू के टुकड़े

- भुना हुआ नमकीन काजू के टुकड़े

- जैविक बीज (छिलके वाले)

- पेकान के टुकड़े

- कच्चे ब्राज़ील नट्स

- कच्चे मैकाडामिया नट्स

- कच्चे पेकान

- शुगर इकुमा 45

- ब्राउन शुगर

- बिक्री के लिए पूरा नीला केकड़ा।

- शिपमेंट के लिए स्टॉक रेडी ब्लू स्विमिंग क्रैब

- मेक्सिको से ब्लू स्विमिंग क्रैब

- बिक्री के लिए लाइव फ्रेश ब्लू क्रैब।

- बिक्री के लिए नीला केकड़ा।

- बिक्री के लिए फ्रोजन ब्लू क्रैब।

- बिक्री के लिए लाइव फ्रेश क्लीन होल किंग क्रैब।

- बिक्री के लिए बड़े लाइव ऑयस्टर

- फ्रोजन ऑयस्टर शेल्स के साथ

- बिक्री के लिए लाइव फ्रेश क्लीन होल क्रॉफिश।

- रेमी मार्टिन

- ऑर्गेनिक कोको निब्स को मीठा किया गया

- जैविक केले का पाउडर

- ऑर्गेनिक चिया पाउडर

- ऑर्गेनिक क्लोरेला पाउडर (क्रैक सेल)

- ऑर्गेनिक मोरिंगा पाउडर

- ऑर्गेनिक नारियल का आटा

- ऑर्गेनिक जिलेटिनाइज्ड मैका पाउडर

- ऑर्गेनिक गोजी बेरी पाउडर

- जैविक साबुत अलसी

- ऑर्गेनिक स्पिरुलिना पाउडर

- कच्ची उबली हुई मूंगफली

- कच्चे पिस्ता की गुठली कैलिफ़ोर्निया

- सन का बीज

- ऑर्गेनिक हल्दी पाउडर

- कच्चे हेज़लनट्स/फ़िलबर्ट्स

- हल्के उबले हुए हेज़लनट्स

- भुना हुआ नमकीन काजू 320

- चॉकलेट से ढके मैकाडामिया नट्स

- कद्दू की गुठली, कद्दू के बीज (कच्चे, कोई खोल नहीं)

- कच्चे पाइन नट्स

- ब्राज़ीलियाई रिफाइंड ब्राउन शुगर इकुम्सा 150-600

- लाइव लॉबस्टर

- चिया के बीज

- चॉकलेट मूंगफली

- चॉकलेट से ढके पेकान

- चॉकलेट मूंगफली के रत्न

- कोको बादाम

- गोजी बेरीज

- बिक्री के लिए लाइव फ्रेश क्लीन होल ब्लू क्रैब।

- जैविक चिया बीज

- ऑर्गेनिक कोको पाउडर

- ताज़ी हरी इलायची

- ताजा लहसुन

- लाल मूँगफली

- पेकन नट्स

- पाइन नट्स

- पिस्ता मेवे

- बादाम के दाने

- कैलिफोर्निया बादाम

- खूबानी की गुठली

- सुपारी

- क्वालिटी ग्रेड ए वॉलनट्स

- जीरा

- तिल के बीज

- डार्क ब्राउन कोको पाउडर

- उत्तम गुणवत्ता वाली हरी इलायची

- आलू के गुच्छे

- गुणवत्ता वाले आलू के गुच्छे

- उच्च गुणवत्ता वाले आलू के गुच्छे

- चिकन फीट

- ताजा चिकन फीट

- थोक चिकन फीट

- उच्च गुणवत्ता वाले गैर जीएमओ पीले सोयाबीन

- अम्ल

- कृषि उत्पाद

- लेडी रोसेटा लाल आलू

- सफेद लहसुन

- निर्यात के लिए प्रीमियम क्वालिटी स्प्लिट रेड लेंटिल्स

- सफेद और पीला मकई/मक्का ग्रेड 1

- पीला मकई

- ऑर्गेनिक नारियल चीनी

- बिक्री पर सबसे अच्छी गुणवत्ता वाली काली मिर्च

- हरी इलायची उपलब्ध

- हरी इलायची - 7.5-8mm

- रोबस्टा कॉफ़ी (ग्रेड ए) और अरेबिका कॉफ़ी बीन्स (ग्रेड ए)

- हरी कॉफी बीन्स/अरेबिका कॉफी बीन्स

- सबसे अच्छी गुणवत्ता वाली हरी इलायची सबसे अच्छी कीमतों पर बिक्री के लिए

- उच्च गुणवत्ता वाली अरेबिका भुनी हुई कॉफी बीन्स

- अरेबिका कॉफ़ी बीन

- उच्च गुणवत्ता वाला रोबस्टा/हरा/भुना हुआ/ताज़ा/अरेबिका

- काली मिर्च

- हरी कॉफी बीन्स/अरेबिका कॉफी बीन्स/कच्ची कॉफी बीन्स बिक्री के लिए सस्ती कीमत

- अरेबिका कॉफ़ी बीन्स

- अरेबिका रोस्टेड कॉफ़ी बीन उपलब्ध

- बिक्री पर काली मिर्च

- सफेद ताजा लहसुन उपलब्ध

- शुद्ध ताजा सफेद लहसुन

- ताजा लहसुन की कलियां उपलब्ध

- ताजा लहसुन

- सफेद लहसुन और लाल लहसुन उपलब्ध

- ताजा लहसुन की कलियां

- सूखे पीले मकई बिक्री के लिए उपलब्ध

- सूखा मक्का/सूखा पीला मकई/ड्राइड स्वीट कॉर्न सर्वोत्तम मूल्य प्रतिस्पर्धी मूल्य

- गैर जीएमओ सफेद/पीला मक्का मकई थोक में आपूर्ति के लिए तैयार

- मानव और पशु आहार के लिए पीला मकई/मक्का और सफेद मकई/मक्का

- किडनी बीन्स

- उच्च गुणवत्ता वाले किडनी बीन्स

- मूंगफली शैल में

- ब्राज़ील नट्स

- काजू

- क्वालिटी चेस्टनट

- सूरजमुखी के बीज

- ग्रेड ए क्वालिटी हेज़लनट्स

- क्वालिटी पेरिला सीड्स

- मैकडामिया नट्स

- शीर्ष गुणवत्ता वाले सोयाबीन

- येल्लो कॉर्न

- क्वालिटी व्हाइट कॉर्न

- शीर्ष गुणवत्ता वाले वेनिला बीन्स

- ग्रेड ए किडनी बीन्स

- थोक छोले

- मूंग की फलियाँ

- रॉ कोको बीन्स

- उच्च गुणवत्ता वाला सफेद और लाल सोरघ/गेहूं

- प्रीमियम ग्रेड मोरिंगा के बीज

- हरी, लाल और भूरी दाल

- ग्रेड ए ब्लैक आई बीन्स

- ग्रीन कॉफ़ी अरेबिका बीन्स कॉफ़ी बीन्स

- अल्फाल्फा हे सीड्स

- उच्च गुणवत्ता वाली दाल/लाल दाल/हरी दाल

- 100% ऑर्गेनिक आलू

- ऑर्गेनिक आलू

- ताजा आलू

- थोक मूल्य जटरोफा बीज उपलब्ध

- लेडी रोसेटा आलू

- लेडी रोसेटा आलू

- ग्रीन कॉफ़ी बीन्स

- प्लास्टिक एवं उत्पाद

- ऊर्जा शक्ति

- लकड़ी का छर्रा

- उच्च ऊर्जा वाली लकड़ी की गोली

- अच्छी गुणवत्ता वाली कार टायर कार टायर 175 70r13 425/85 r21

- हॉट सेलिंग वुड पेलेट्स पाइन वुड पेलेट 6 मिमी

- 15 किलो बैग में वुड पेलेट, डीआईएन प्लस, एन प्लस-ए1 (6-8 मिमी) पाइन, बीच, स्प्रूस, फ़िर, बबूल और ओक बीएसएल प्रीमियम क्वालिटी बायोमास ईंधन बिक्री के लिए

- बिक्री के लिए वुड पेलेट्स यूरोप के छर्रों

- फैक्ट्री प्राइस बल्क सेलिंग कॉमन कल्टीवेशन टाइप जेट्रोफा सीड ऑयल

- स्वास्थ्य व सौंदर्य

- नई शादी का घूंघट

- इस्तेमाल किए हुए कपड़े

- गुणवत्ता वाले इस्तेमाल किए गए दूसरे हाथ के कपड़े

- इस्तेमाल किया हुआ जूता

- फ्लोरल परफ्यूम

- मिश्रित आलीशान परफ्यूम

- नए मिश्रित शानदार परफ्यूम

- पुरुषों और महिलाओं के लिए फैक्ट्री होलसेल यूनिसेक्स परफ्यूम ओरिजिनल

- थोक यूनिसेक्स परफ्यूम मूल

- नया परफ्यूम

- थोक परफ्यूम

- सस्ता परफ्यूम

- शानदार परफ्यूम

- नए असॉर्टेड परफ्यूम

- थोक 100 मिलीलीटर पुरुषों और महिलाओं के परफ्यूम हाई-एंड लक्ज़री परफ्यूम सभी प्राकृतिक लंबे समय तक चलने वाले बॉडी परफ्यूम स्प्रे

- 100% शुद्ध प्राकृतिक परफ्यूम

- प्राकृतिक स्वाद और खुशबू वाला परफ्यूम

- वेडिंग गाउन

- नाइस वेडिंग गाउन

- शादी का घूंघट

- क्लासिकल डिज़ाइन में लग्ज़री घड़ियाँ

- क्लासिकल डिज़ाइन घड़ियाँ

- कलाई घड़ियाँ

- लक्जरी कलाई घड़ियाँ

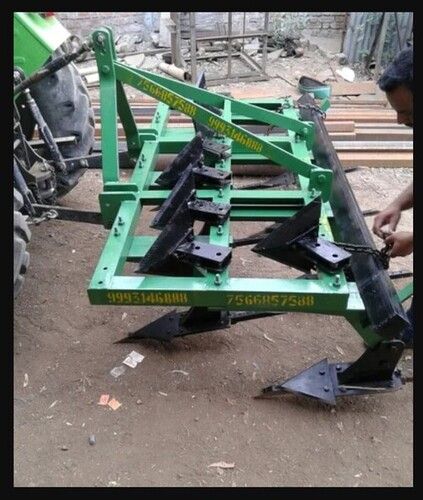

- मशीनरी

- खनिज एवं धातु

- परिवहन

- निर्माण एवं रियल एस्टेट

- संपर्क करें

Rice Transplanter

X

मूल्य और मात्रा

- 50

व्यापार सूचना

- Durban

- , , , ,

- प्रति महीने

- दिन

- Yes

- Cartons

- , , , , , , , ,

उत्पाद विवरण

This rice planter is our new design rice planter , it design with a long frame and wide pedal design, it can carry more seedlings at one time, reduce the number of seedlings, save time and improve work efficiency

It has the main feature as following

long frame and wide pedal

Four-wheel drive and extended wheelbase

High-strength rear axle design and high-strength frame chassis

High strength rear axle design and high strength frame chassis structure design, the fuselage is firm, strong, strong tensile deformation ability

Scene Picture

Efficient Rice Transplanting Solution

Our Rice Transplanter is designed for speed and precision, making rice cultivation more streamlined for South African farmers. With an adaptable engine typediesel or petrolthis machine fits various field conditions and grower requirements. Its six-row configuration and compatible tray capacity increase operational productivity, while the compact turning radius enhances its usability, even in fields with tight corners. This is a powerful upgrade for anyone looking to maximize their rice harvesting potential.

Flexible for Different Agricultural Needs

This rice transplanter seamlessly accommodates seedlings aged 12 to 30 days, suiting diverse farming schedules. It is available both as manually operated and engine-driven models, ensuring the right solution for plots of various sizes and budgets. The machines adjustable planting speed and high tray capacity allow continuous, large-scale operations, reducing manual labor and enabling consistency in planting for optimal crop yield.

FAQs of Rice Transplanter:

Q: How does the rice transplanter benefit South African rice farmers?

A: The rice transplanter significantly reduces manual labor by automating the planting process for up to six rows at once. Its efficiency increases field capacity to 0.160.26 hectares per hour, allowing farmers to cover more ground quickly and achieve uniform transplanting, leading to healthier crops and improved yields.Q: What are the engine options for this rice transplanter, and which fields are they best suited for?

A: Models come with diesel or petrol engines, with some versions available as manually operated. Diesel engines are suited for larger, continuous fields due to fuel efficiency, while petrol and manual models are ideal for smaller or irregularly shaped plots. Choose based on field size and available resources.Q: When is the best time to use this rice transplanter during the planting season?

A: The transplanter is designed for seedlings aged between 12 to 30 days. For optimal results, use the machine when your rice seedlings fall within this age range, ensuring successful transplantation and healthy crop development.Q: Where can I purchase this rice transplanter in South Africa?

A: The rice transplanter is available through various official dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across South Africa. Contact a local agricultural machinery supplier for availability and service support.Q: What is the recommended planting distance and how does it affect rice crop growth?

A: This transplanter maintains a precise planting distance of 210 mm between rows. Such consistent spacing promotes good air circulation, even nutrient distribution, and reduces plant competition, which collectively enhances the overall yield and health of the crop.Q: How is the machine operated and maintained?

A: Depending on the model, operation may be manual or engine-driven. Regular maintenance includes checking the engine (for petrol/diesel models), cleaning trays, lubricating moving parts, and inspecting for wear. Follow the manufacturers manual for specific maintenance intervals and operational guidance.Q: What process does the machine follow for transplanting, and how does this improve productivity?

A: The transplanter collects seedlings from its tray (holding up to 20 kg), spaces them at 210 mm intervals, and plants six rows simultaneously. This automated process accelerates fieldwork compared to manual methods, lowers labor costs, and delivers consistent, professional-grade planting.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email